We firmly believe the best accuracy from a belt scale is achieved with correct routine calibration, idler roller maintenance and original spare parts. Our belt scale service team can provide everything from over the phone advise to comprehensive, all inclusive, onsite service backed by in-stock spare parts.

TC Process Equipment can service all makes and models of belt scales. We also have comprehensive engineering resources to design replacement parts to service redundant units. Our control unit can be used with all load cell base work (all current manfacturers).

Safety is without compromise when working in industrial and mining environments. We have a detailed Work Health and Safety Manual, TCM0022, which outlines our safety procedures and is available for review prior to any work. We provide qualified service technicians with PPE (hard hat with ear muffs, high-visibility reflective shirt, steel caped lace up boots, 2 x personal isolation locks (each person) and each work crew carries programmable handheld 5W UHF radio. Workers covered by NSW Work cover (iCare) and Coal Mines Insurance (CMI). Fully equipped site 2WD ute with roof mounted amber flashing light, reflective high-visibility flag 3.2m high, BCF 1kg fire extinguisher and First Aid Kit. Safe Work procedures can be submitted before site attendance, SWMS, JSEA and “Take 5” forms are completed before all work. We supply all our own tools as required.

All our service is logged via a secure internet onto your specific site and belt scale. Comprehensive calibration records are kept of all work done by our service technicians.

As much as possible we have a policy of 1 crew, same site. This means we have the same persons attend your site as required. We find this builds a mutually beneficial familiarity of site which improves service and aids communication

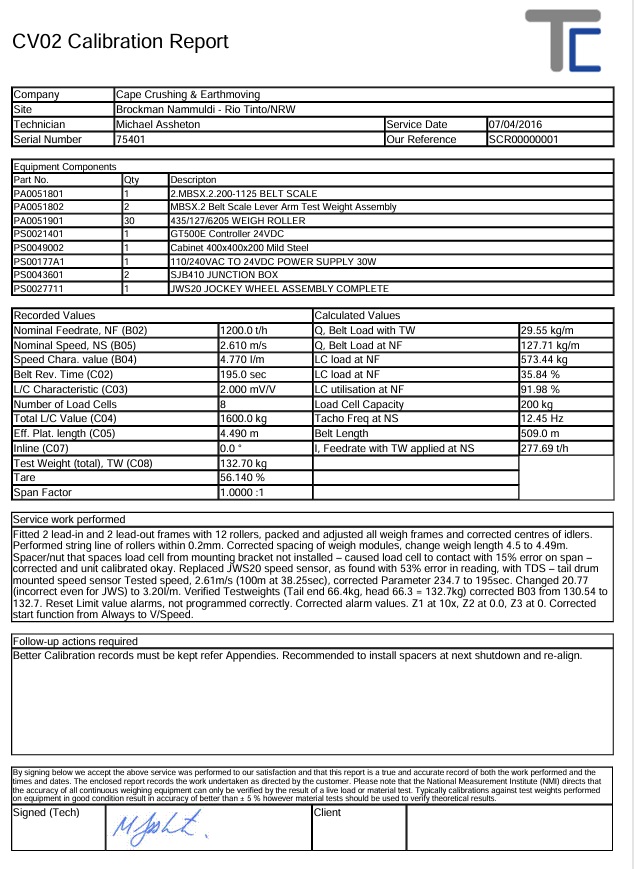

Periodic Calibration - Tare (Zero Point), Span (Check Weight) and Material TestingIt is recommended that all belt scales be routinely calibrated. The frequency of calibration is determined specific to each site or belt scale and is subject to the environment, duty of the conveyor and material conveyed. We would be pleased to review your requirements and provide specific recommendations for your routine calibrations. As a general guide every 1 to 3 months at a minimum with the frequency of calibration increasing if discrepancies are noticed. While routine calibrations can be done by the site operator, many sites prefer to have TC Process these routine calibrations as; - We are independent and can provide and audit of past calibration records - We provide a comprehensive calibration report - We have certified calibration weights, we can verify your calibration weights - We offer speed calibration services and idler checks All Calibration data is stored on-line and can be exported for reporting and conciliation.

|

|

Belt Speed - Calibration or VerificationWe offer speed calibration services accurate to 1 millisecond (per metre). After safely isolating the belt, we place reflective strips on the belt and a photoelectric sensor over the belt. the belt is then de-isolated and run for a minimum of 3 revolutions. This accurately measures the; - Current belt speed (metres per second - Belt Revolution Time (second) - Belt Length (m) Accurate speed measurement and calibration is as important to belt scale accuracy as the weight calibration. Speed error has an equal proportion of error as weight errors. |

|

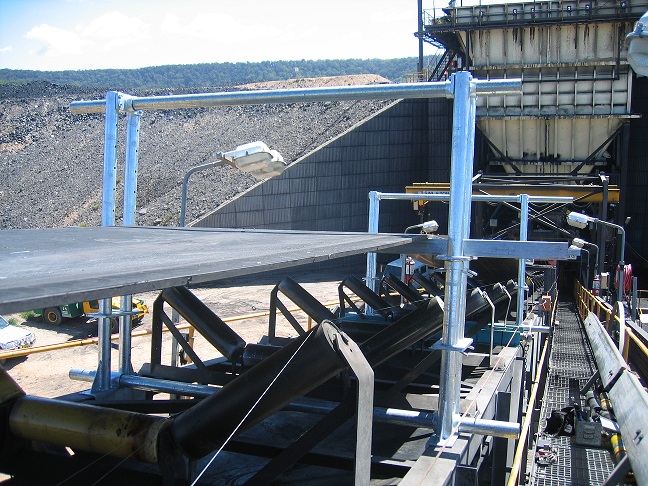

Weigh idler Service - replacement and alignmentIdler alignment is the most common cause of errors on conveyor belt scales. As a rough guide 0.2mm of mal-alignment on a conveyor idler in the weigh idler influence zone can cause an additional 1% error on the belt scale (subject to feed rate and belt speed). TC Process offers a comprehensive alignment or replacement service. We also use our own certified belt lifting equipment. We offer a 24 hr emergency idler fabrication service for failed idlers as well as planned idler re-alignments and complete roller change out. We can offer a idler management plan based on you site requirements. |

|

Conveyor Belt Lifting equipmentOne of the major considerations in the service of conveyor belt scales is the management of the belt. To be able to service or repair belt scales in most cases the conveyor belt must be lifted and must not be classified as a "suspended load" as technicians will be required to work under the lifter belt. As part of our serving capabilities we offer our belt lifting equipment. Our belt lifters are independently certified to AS1170.0:2002 and AS1170.1:2002 (Structural Design actions). They lift the belt and, if installed, the gravity take-up up to 2m wide belt with 8 ton take-up mass. The lifters break down into parts no more than 15kg each part for ease of manual handling. They can be used inside of tunnel, covered conveyor or fully underground. The system uses self contained hydraulic jacks to lift and lower the belt. The belt lifters have been applied to lift conveyor belt which contain a single, dual or four idler belt scale, with one lift of the belt enables continuous free alignment of all the weigh idlers. Available as part of a service contract, once off service or dry hire. |

|

Installation and CommissioningInstallation of belt scales requires skills which span multiple trades. The belt scale location in the conveyor must be selected to ensure the correct belt loading at all running conditions. The belt scale then must be expertly installed giving consideration to the high tolerances and precision of the elements involved. We offer competitive hourly rates or fixe price fixed price installation. We can arrange all services (Electrical/Mechanical) and hire of specific tooling including EWP, Generators, Cut-off Saw, Magnetic Base drills and Welding equipment. |

|

Belt Scale Verification - Trade or Non-tradeTC Process Equipment can arrange verification (material testing) of belt scales. We offer mass balance, belt cut and legal-for-trade to the National Measurement Institute (NMI) NMI R50-1 certification. NMI’s Chief Metrologist has determined that NITP 6.5 contains the test procedures for the verification of continuous totalising automatic weighing instruments (belt weighers). We can also calibrate the control instrument. |

|